News

Holding North American Manufacturing Together

Choosing the Right Inkjet Technology for Variable Data on High-Speed Packaging Lines

Variable data printing—including date codes, lot codes, barcodes, and serialization—is a critical function on high-speed packaging lines. When print quality fails, the result is often rework, scrap, or rejected shipments. Selecting the right inkjet printing technology ensures consistent codes without slowing production.

Two technologies dominate industrial packaging applications: continuous inkjet (CIJ) and high-resolution drop-on-demand (DOD) inkjet. The right choice depends on line speed, substrate, and print requirements.

Why Inkjet Selection Impacts High-Speed Packaging Performance

As packaging line speeds increase, print windows become shorter and substrates less predictable. Inkjet systems that aren’t properly matched to the application can cause:

- Incomplete or distorted codes

- Barcode scan failures

- Increased rejects and rework

- Downtime tied to print quality troubleshooting

Matching inkjet technology to the packaging environment is essential for maintaining throughput and compliance.

Continuous Inkjet (CIJ) for High-Speed Variable Data Printing

CIJ printers are designed for high-speed packaging lines that require reliable variable data printing across a range of substrates.

CIJ Best-Fit Applications:

- Fast-moving cartons and cases

- Uneven or inconsistent package positioning

- Corrugated, coated cartons, films, and shrink wrap

- Date coding, lot coding, and serialization

Because CIJ systems print without direct contact and tolerate variation in product movement, they perform well where speed and flexibility matter most.

MAP supports CIJ solutions from Hitachi – Learn more about MAP’s Hitachi CIJ printers

High-Resolution Drop-on-Demand (DOD) Inkjet for High-Resolution Packaging Codes

High-resolution drop-on-demand inkjet printers are optimized for applications where print clarity and barcode readability are the top priorities.

DOD Best-Fit Applications:

- Moderate-speed packaging lines

- Large character printing

- High-contrast barcodes on corrugated cases

- Secondary packaging identification

DOD systems excel when scanning reliability and visual clarity are more important than maximum line speed. MAP offers DOD solutions from Squid Ink for case-level printing applications.

Learn more about MAP’s Squid Ink DOD printers

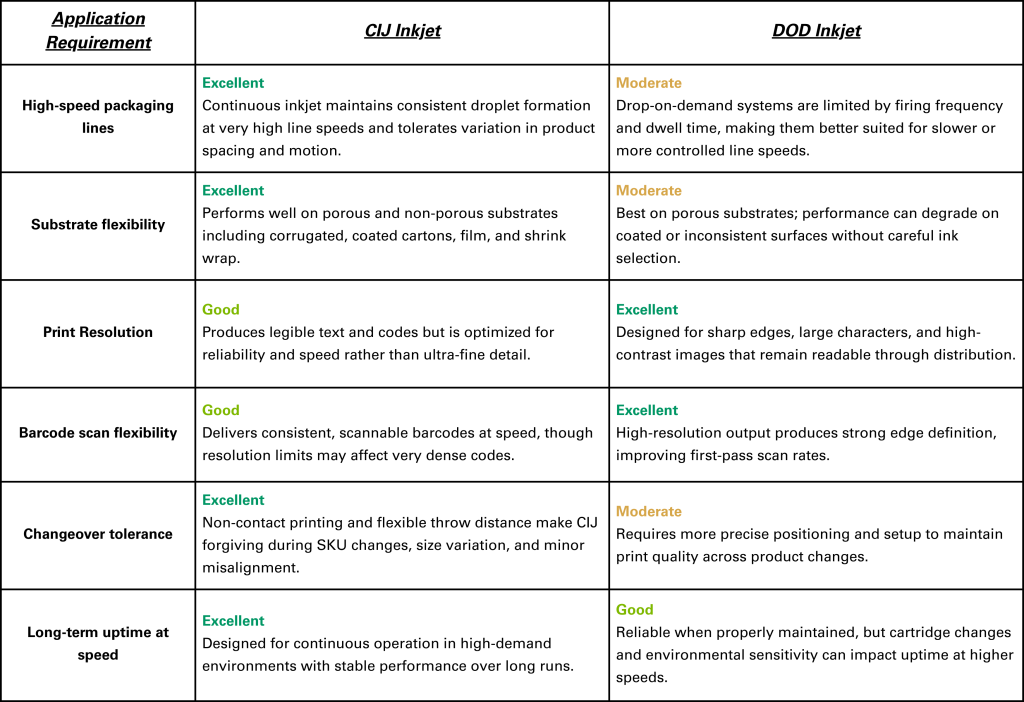

CIJ vs. DOD: Packaging Line Comparison

Selecting the correct system reduces rejects, improves uptime, and supports future line speed increases.

Reducing Rework by Matching Technology to the Application

In one MAP-supported packaging operation, barcode rejects were traced to print inconsistency at higher line speeds. By transitioning to a CIJ system better suited to the substrate variation and speed, the facility reduced rework, stabilized barcode scans, and improved overall line efficiency.

This outcome highlights a common reality: print failures are often technology mismatches, not operator errors.

How to Choose the Right Inkjet Printer for Your Packaging Line

Before selecting an inkjet system, consider:

- Current and future line speeds

- Packaging substrates and coatings

- Required print resolution

- Barcode scanning requirements

- Changeover frequency

MAP helps manufacturers evaluate these factors and select solutions that support production goals and reduce long-term operating costs.

Want to discuss what solution is right for your production line? Contact your MAP representative today! – Contact us

Want to discuss what solution is right for your production line? Contact your MAP representative today! – Contact us

To speak with someone immediately, call: (314) 652-4583

For more information or questions, email us at: info@map-pack.com

Follow us on LinkedIn & Facebook for more tips, resources, and updates!